Automation

Automation

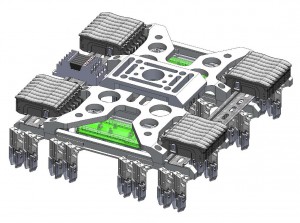

Crosslink engineers design and fabricate custom solutions to improve the manufacturing process. Services include automation and robotic systems, packaging and assembly stations, as well as training, and maintenance services.

Custom design and build capabilities:

High Accuracy End Of Arm Tooling (EOAT)

Cavity Separation Units (CSU)

Manual, Semi-Auto or Fully Automatic Assembly Stations

- Vacuum pickup with pressure sensor

- Gripper pickup with built-in sensors for part verification

- Runner extraction with built-in sensors for verification

- In process defect detection (application dependent)

- In process degating (application dependent)

- Handshake signals to robot to indicate all parts being pickup or off loaded

- Optional feature to allow selective cavity reject independent of the robot

- Separates parts into individual cavity ID

- Reduce scrap by allowing only the defective cavity to be thrown out

- Degating stations

- Ensures gate tolerance spec consistency

- Ergonomically designed with emphasis on operator safety

- Custom Robot Safety Guards and Conveyor Systems

- Inspection Tables